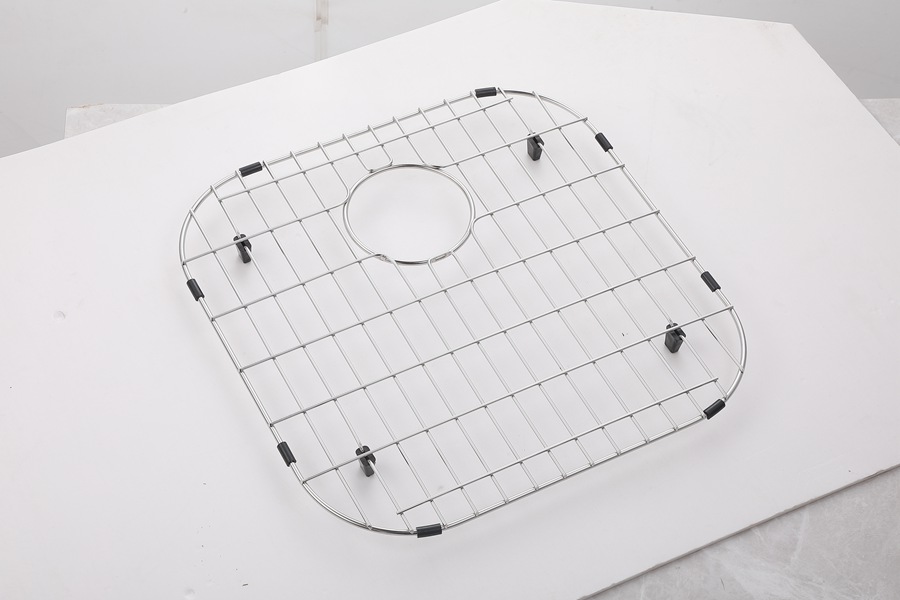

Sink Bottom Grate is a stainless steel grid at the bottom of the sink, which is an important accessory for filtering and protecting the bottom of the sink in the kitchen. It is rectangular in shape, with a fine and uniform metal mesh structure as the main body. The longitudinal and transverse stainless steel wires are interwoven and welded to form multiple square grids with a circular hole in the middle.

| Dimensional Tolerance | ±2mm |

| Weight Tolerance | / |

| Design Style | Modern |

| Application | Kitchen |

| Product Name | Sink Bottom Stainless Grid |

| Bowl Shape | / |

| Place Of Origin | Guang Dong,China |

| Model Number | Customized Model Number |

| Installation Type | Standing Type |

| Material | Stainless Steel |

| Color Of Material | Bright Silver |

| Color Of Plastic | Black Or Grey |

| Use | Filter Water |

| Brand | Accept Customization |

| Finishing | Electrolytic Polishing |

| Shape | Rectangle |

| MOQ | 100pcs |

| Packing | Carton |

| Port | Guangzhou,Shenzhen |

| Transport | To Be Negotiated |

| Supply Ability | 20000 Pieces Per Month |

Material properties: Made of 304 stainless steel, it has a very high hardness of 80-85 Rockwell hardness (HRB), which can effectively resist the scratches and bumps of various hard objects in daily use, ensure the shape and structure of the grille is stable, and is not easy to deform after long-term use. In addition, stainless steel has excellent corrosion resistance. When facing sewage and detergents containing salt, acid or alkaline components in the kitchen environment, it can still maintain its own performance and appearance. The normal service life can reach more than 8-10 years. After 1000 hours of salt spray test, there is no obvious rust on its surface, and the corrosion rate is less than 0.01mm/year, which is much better than other similar products made of ordinary materials.

Dimensional accuracy: Following strict dimensional standards, the deviation of the length, width and height of the product from the design drawings is controlled within ±2mm, thanks to the precise mold manufacturing and production process. Taking the common grille size of 450mm×350mm×20mm as an example, the maximum error between the actual measured value of its length and the standard length does not exceed 2mm, and the same is true in the width direction, ensuring that it can accurately fit sinks of different sizes, and fit tightly with the inner wall of the sink after installation to avoid excessive gaps that cause debris to get stuck or water flow to hit the bottom of the sink. After actual measurement and statistics, the size qualification rate of 100 products can reach more than 98%.

Weight stability: During the production process of each product, due to the uniformity of the material and the stability of the manufacturing process, the weight error can be ignored and basically remains within a very small fluctuation range. For example, for a grille with a size of 450mm×350mm×20mm, the standard value of a single piece weight is 320 grams, and the actual product weight deviation does not exceed ±5 grams. In this way, during transportation, installation and use, there is no need to worry about the overall balance and stability being affected by excessive weight differences, which is also conducive to product quality control and cost accounting.

Surface treatment: After electrolytic polishing, the surface presents a bright silver luster, and the reflectivity can reach 75% - 80%. It is not only beautiful in appearance, but also easy to clean and maintain. It is difficult for stains and water stains to adhere to its surface. It is more convenient and quick to clean. It can be restored to brightness by simply rinsing with clean water or wiping it. In addition, this treatment method can further enhance its corrosion resistance and extend its service life. The surface roughness after electrolytic polishing can be reduced to Ra0.2 - 0.4μm, which is smoother and flatter than Ra0.8 - 1.6μm before polishing, reducing the possibility of dirt adhesion.

Structural design: The size of the grid has been carefully designed and calculated, and the spacing between two adjacent longitudinal or transverse stainless steel wires is 5mm, which can not only ensure the smooth passage of water, effectively filter out various debris, such as vegetable leaves, food residues, etc., to avoid debris blocking the sewer pipes, but also prevent smaller tableware, knives and forks from falling to the bottom of the sink and directly contacting the water flow, reducing the risk of the bottom of the sink being scratched. At the same time, the circular hole in the middle corresponds precisely to the drain outlet of the sink to ensure smooth drainage. According to tests, its filtration efficiency can reach more than 95%, and it can effectively intercept solid particles with a diameter greater than 3mm, ensuring the unobstructed drainage system.

Home kitchen field: In home kitchens, Sink Bottom Grate is an essential sink accessory. When people perform daily food cleaning work, such as cleaning vegetables, fruits, meat and various tableware, it can effectively filter out the leaves, peels, food residues and other debris generated during the cleaning process, preventing these debris from entering the sewer pipes with the water flow and causing blockage.

Catering industry kitchen field: In restaurants, hotels and other catering industry kitchens, Sink Bottom Grate plays a vital role. When chefs handle a large number of ingredients and wash many tableware, a large amount of food residue and sewage will be generated. Its installation can effectively intercept these residues, avoid clogging the sewer pipes, and reduce the maintenance cost of the kitchen drainage system. For example, when cleaning seafood, the viscera, shells and other debris of seafood will be intercepted by the grille to ensure the smooth drainage pipes, while also maintaining the sanitary environment of the kitchen and improving the kitchen work efficiency.

Laboratory sink field: In various laboratories, sinks are used to clean experimental equipment and treat wastewater generated by experiments. Sink Bottom Grate can effectively filter out small solid waste generated during the experiment, such as precipitates of chemical reagents, residues of experimental samples, etc. For example, when cleaning beakers and test tubes in a chemical laboratory, the residual chemical precipitates will be intercepted by the grate to prevent them from entering the drainage system and corroding or clogging the drainage pipes. At the same time, it is also convenient for centralized cleaning of experimental waste to ensure the normal operation of the laboratory drainage system and the cleanliness of the experimental environment.

Industrial production sink field: In some industrial production workshops, such as food processing plants and pharmaceutical plants, sinks are used to clean raw materials, semi-finished products and production tools. Sink Bottom Grate can effectively filter out debris such as raw material debris and packaging material fragments generated during the production process to ensure the smooth flow of the drainage system. Taking a food processing plant as an example, when cleaning fruit raw materials, fruit branches, leaves, rotten fruits and other debris will remain on the grate, which is convenient for workers to clean up, avoid debris from mixing into the drainage system to affect water quality and block pipes, and ensure the smooth progress of the industrial production process.

Sink Bottom Grate in public facilities: Sinks in school cafeterias, hospital kitchens, public toilets and other places also play a key role. In public cafeterias, a large number of people will lead to frequent use of sinks and produce a lot of food residues. The grate can effectively filter these residues and keep the drainage unobstructed; in hospital kitchens, it can ensure smooth drainage during the cleaning process of medical food and avoid clogging caused by debris. Health problems; in public toilets, it can intercept the residues of toiletries, etc., maintain the normal operation of public drainage facilities, and improve the user experience and maintenance efficiency of public facilities.

Cleaning and maintenance: After each use of the sink, the debris on the Sink Bottom Grate should be cleaned in time. First, rinse the grate with clean water to wash off the leaves, peels, food residues, etc. attached to the surface. For more stubborn stains, such as dried oil stains and stubborn scale, you can use a special detergent to wipe them, but be careful not to use detergents containing strong acid and alkali ingredients to avoid corrosion to the stainless steel material. For example, for oil stains, you can use a small amount of neutral detergent and a soft cloth to gently wipe, then rinse with clean water, and finally wipe dry with a dry cloth to keep its surface clean and dry to extend its service life.

Storage and maintenance: When the Sink Bottom Grate is not in use, it should be stored in a dry and ventilated place. Avoid placing it in a humid environment to prevent the stainless steel material from getting damp and rusting. If it is not used for a long time, a thin layer of cooking oil can be applied to its surface to form a protective film to further prevent moisture and oxygen in the air from corroding the stainless steel. For example, before the rainy season arrives, wash and dry the grille, apply cooking oil, put it in a sealed plastic bag, and place it in a dry place in the cabinet to effectively prevent rust.

Anti-collision maintenance: During daily use, care should be taken to avoid heavy or sharp objects colliding with the Sink Bottom Grate. When placing or taking out larger and heavier items in the sink, such as pots and chopping boards, they should be handled with care to avoid deformation of the grille or scratching its surface. If the grille is accidentally damaged by a collision, it should be repaired in time. For example, if there are slight scratches on the surface, you can use a stainless steel-specific polishing agent to polish it to restore its bright surface. If the deformation is serious, a new grille needs to be replaced to ensure its normal use function.

Regular inspection and maintenance: The Sink Bottom Grate should be inspected regularly to check whether the anti-skid pads of its supporting feet are severely worn. If the anti-skid pads are excessively worn, the grille will be unstable in the sink and easy to shake, affecting the user experience. The anti-skid pads should be replaced in time. At the same time, check whether the stainless steel wire is loose or broken. If there is any loose or broken stainless steel wire, the entire grille should be repaired or replaced in time to prevent further damage and ensure the normal function of its filtering function. It is recommended to conduct a comprehensive inspection and maintenance every two months.

Disinfection and maintenance: In order to ensure kitchen hygiene, the Sink Bottom Grate should be disinfected regularly. You can use a special tableware disinfectant, dilute it according to the requirements of the instructions, soak the grille in it for a period of time, and then take it out and rinse it with clean water. For example, using tableware disinfectant to disinfect it once a week can effectively kill bacteria, viruses and other microorganisms remaining on the grille, prevent odor, ensure the sanitary environment of the kitchen sink, and protect people's health.

Jiangmen Pengjiang District Zhengyong Hardware Co., Ltd.

Jiangmen Pengjiang District Zhengyong Hardware Co., Ltd. was founded in 2017. Since its establishment, the company has obtained CUPC certification and is based on the ISO90001:2015 quality management system. The company specializes in the production of kitchen and bathroom supporting shelves, sink racks, drain baskets and other hardware products. Adhering to the business philosophy of "quality first and marketing first" and management as the soul, we have established internal R&D, production and other departments. We are a professional kitchen and bathroom hardware accessories manufacturing company integrating R&D, design, production and sales. The products have novel styles and stable quality, and can be customized according to customer needs.

On the basis of absorbing advanced domestic and foreign technologies and years of experience in kitchen and bathroom hardware supporting products, the company's product production stability and reliability have been recognized and trusted by cooperative customers. While creating high-quality kitchen and bathroom hardware products and improving the quality of life, the company insists on using corporate culture to enhance the core competitiveness of the company, so that the company can establish a correct and good social image in its development. Maintain long-term cooperative relationships with domestic first-tier brand companies.

"Professional", "reliable" and "accurate" are our company's production spirit and service belief. It is precisely because of this that our company's products are sold at home and abroad and in major and medium-sized cities in China, and are well received and praised by users. We strictly ensure that product quality passes the test. Every piece of fine quality. As the company continues to develop, Zhengyong will adhere to the business philosophy of pioneering innovation and advancing with the times, producing in China and facing the world.