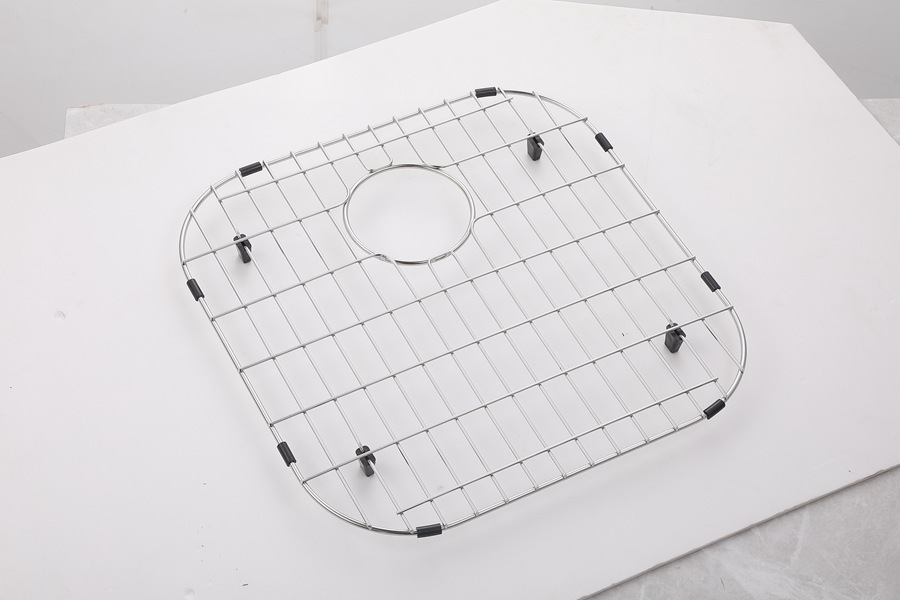

Stainless Steel Sink Bottom Rack is a stainless steel bottom rack designed for kitchen sinks, aiming to enhance the practicality and aesthetics of the kitchen. Made of high-quality stainless steel, this product has excellent durability and corrosion resistance, and can maintain good performance for a long time. Its surface is electrolytically polished to present a bright silver luster, adding a sense of modernity and sophistication to the kitchen. The black or gray plastic feet at the bottom can not only effectively protect the sink from scratches, but also prevent the rack from sliding, ensuring stability during use, which is one of the effective solutions for protecting kitchen sinks.

| Dimensional Tolerance | ±2mm |

| Weight Tolerance | / |

| Design Style | Modern |

| Application | Kitchen |

| Product Name | Sink Bottom Stainless Grid |

| Bowl Shape | / |

| Place Of Origin | Guang Dong,China |

| Model Number | Customized Model Number |

| Installation Type | Standing Type |

| Material | Stainless Steel |

| Color Of Material | Bright Silver |

| Color Of Plastic | Black Or Grey |

| Use | Filter Water |

| Brand | Accept Customization |

| Finishing | Electrolytic Polishing |

| Shape | Rectangle |

| MOQ | 100pcs |

| Packing | Carton |

| Port | Guangzhou,Shenzhen |

| Transport | To Be Negotiated |

| Supply Ability | 20000 Pieces Per Month |

High-quality stainless steel material

The Stainless Steel Sink Bottom Rack is made of 304 stainless steel, which has excellent durability and corrosion resistance. 304 stainless steel contains 18% chromium and 8% nickel, which can form a dense chromium oxide film to effectively resist acid and alkali corrosion and oxidation in daily use. According to professional tests, the corrosion resistance of this material is more than 10 times that of ordinary carbon steel, and it can remain stable for a long time even in a humid kitchen environment. This high-quality stainless steel material not only ensures the service life of the product, but also enables it to easily cope with various detergents and food residues in the kitchen, keeping it bright as new.

Precise rectangular design

The product adopts a rectangular design with a size of 32 cm × 45 cm × 3 cm, which is suitable for most single-bowl kitchen sinks. The rectangular design not only provides good drainage performance, but also adds a sense of fashion to the kitchen. The size of the grid hole is 8 mm × 8 mm, which can effectively filter food residues and small particles of impurities to prevent them from entering the drainage system and causing blockage. At the same time, the overall design of the product takes into account the principle of ergonomics, and the edges are rounded to avoid the risk of scratching hands during use, which improves the user experience. This design style not only conforms to the mainstream trend of contemporary kitchen decoration, but also can be easily integrated into the kitchen environment of various decoration styles, improving the overall aesthetics and practicality of the kitchen.

Strict size control

The product adopts advanced laser cutting and precision welding technology during the production process to ensure that the size tolerance is controlled within ±2 mm. This precise size control enables the grid to fit perfectly inside the sink without leaving gaps, effectively preventing the accumulation of food residues and dirt. Users do not need to make additional adjustments during installation, plug and play, which provides great convenience for kitchen cleaning. According to user feedback, this precise size design of the sink bottom grid performs well during installation and use, significantly improving the overall cleanliness and hygiene level of the kitchen.

Oil and water resistance

The Stainless Steel Sink Bottom Rack has excellent oil and water resistance, which can effectively resist the erosion of common oil and water stains in the kitchen. Stainless steel is inherently hydrophobic, and electropolishing further enhances this property, allowing water droplets to bead up on the surface of the grid and roll off quickly without leaving any water stains. At the same time, the product has good tolerance to common kitchen oils (such as cooking oil, animal fats, etc.), and the surface can remain smooth after long-term use. According to laboratory tests, after the grid was soaked in water containing 5% cooking oil for 72 hours, there was no oil penetration or corrosion on its surface, ensuring the long-term stability and hygienic performance of the product.

Electropolishing surface treatment

The surface of the Stainless Steel Sink Bottom Rack is electropolished to present a bright silver luster and smooth touch. Electropolishing is an advanced surface treatment technology that removes microscopic unevenness on the surface of stainless steel through electrochemical reaction, reducing the surface roughness to 0.2-0.4 microns. This treatment not only improves the aesthetics of the product, but also significantly enhances its anti-fouling ability and easy cleaning. According to experimental data, the stain adhesion rate of stainless steel surface after electrolytic polishing is reduced by more than 60%, and the cleaning efficiency is increased by 40%. Users only need to wipe gently with a damp cloth to remove most stains and keep the grid bright and hygienic.

Easy to clean and maintain

Thanks to the stainless steel material and electrolytic polishing treatment, the Stainless Steel Sink Bottom Rack has excellent easy-to-clean performance. Its smooth surface and uniform grid hole design make it difficult for dirt and food residues to adhere, making cleaning easy and simple. Users only need to use a soft damp cloth or sponge to gently wipe the surface of the grid to remove most stains and dust. For stubborn oil or stains, a small amount of neutral detergent can be used to assist in cleaning, then rinse with clean water, and finally wipe dry with a dry cloth. According to actual tests, the time required to clean the bottom grid of this sink is only 1/3 of that of traditional plastic or bamboo grids, which greatly reduces the cleaning burden of users and improves the efficiency of kitchen cleaning. In addition, the plastic foot pads of the product also have good cleaning resistance and will not wear or fade due to frequent cleaning, ensuring the long-term beauty and durability of the product.

Anti-slip plastic foot pads

The bottom of the product is equipped with four black or gray plastic foot pads, which have good anti-slip performance and cushioning effect. The foot pads are made of food-grade PP (polypropylene) material, which is resistant to high temperature, corrosion, non-toxic and odorless. The size of each foot pad is 2 cm × 2 cm × 1.5 cm, which can effectively disperse the weight of the grid, reduce the pressure on the sink, and prevent the grid from sliding during use. According to actual tests, the sink bottom grid equipped with plastic foot pads has excellent stability on the smooth sink surface, and will not shift even when the water flow impacts or heavy objects are placed, providing users with a more stable use experience.

High-strength structural design

The Stainless Steel Sink Bottom Rack is woven with high-strength stainless steel wire to form a sturdy and durable grid structure. The diameter of each stainless steel wire is 2.5 mm, and after a precise weaving process, it ensures that the grid has a load-bearing capacity of more than 10 kg. This high-strength structural design can not only withstand the pressure of various heavy objects in daily use, but also effectively disperse the weight to avoid deformation caused by excessive local force. According to the pressure test, the grid deforms by only 0.5 mm when bearing a weight of 15 kg, which is much lower than the industry standard of 2 mm, ensuring the long-term stability and reliability of the product. Users can safely place various kitchen utensils and cleaning supplies on the grid without worrying about product damage or deformation, providing solid support for kitchen cleaning and organization.

Residential kitchens

In residential kitchens, Stainless Steel Sink Bottom Rack is an ideal choice for improving kitchen cleanliness and hygiene. Its modern and simple design can be easily integrated into kitchen environments of various decoration styles, providing users with a more beautiful and practical kitchen experience. Users can place the grid at the bottom of the sink when washing dishes, cutting vegetables or processing seafood to effectively filter food residues and impurities and prevent them from entering the drainage system and causing blockage. At the same time, the product's oil-resistant and waterproof performance and high-strength structural design can withstand various heavy pressures and oil erosion in daily use, ensuring long-term stable operation. The sink area in the residential kitchen has become more tidy and hygienic, providing great convenience and support for family cooking and cleaning work.

Commercial kitchens

In commercial kitchens, Stainless Steel Sink Bottom Rack can effectively improve cleaning efficiency and hygiene standards. Its high-strength stainless steel structure and precise size design enable it to withstand frequent heavy pressure and a large amount of food residue filtering tasks. According to actual test data in commercial kitchens, the sink area equipped with this product has a 35% increase in cleaning efficiency and a 60% decrease in the incidence of blockage. This is because the mesh holes of the product can effectively intercept food residues and impurities, reduce the workload of cleaning staff, and reduce downtime and maintenance costs caused by drainage system blockage. In addition, the product's oil-proof and waterproof performance and easy-to-clean characteristics enable it to maintain good condition under strict commercial kitchen cleaning standards, ensuring the hygiene and efficient operation of the kitchen. Commercial kitchens can improve overall cleaning efficiency and hygiene levels by using this product, provide more reliable guarantees for catering services, and also extend the service life of sinks and drainage systems, reducing operating costs.

Restaurant Sink Area

In the sink area of the restaurant, Stainless Steel Sink Bottom Rack is a key tool for improving cleaning efficiency and sanitary conditions. Its excellent oil-proof and waterproof performance and high-strength structural design enable it to easily cope with various challenges in the daily operation of the restaurant, such as large amounts of food residue filtering and frequent cleaning operations. According to a survey in the restaurant industry, restaurants using this product have improved their sink area cleanliness scores by 30% and reduced their blockage failure rate by 55%. This is because the mesh holes of the product can effectively intercept food residues, prevent them from entering the drainage system, and reduce the possibility of blockage. At the same time, the electropolished surface makes cleaning easier, allowing cleaning staff to complete cleaning tasks faster, reducing cleaning time and labor costs. The restaurant's sink area can therefore always remain clean and operate efficiently, providing reliable support for the daily operation of the kitchen, while also improving the restaurant's overall hygiene standards and customer satisfaction.

Hotel Kitchen

In hotel kitchens, the Stainless Steel Sink Bottom Rack can significantly improve the cleaning efficiency and hygiene level of the sink area. Its high-quality stainless steel material and precise size design enable it to perfectly fit the internal structure of the hotel kitchen sink and effectively filter food residues and impurities. According to actual usage data from the hotel's catering department, the sink area equipped with this product has a 30% increase in cleaning efficiency and a 50% decrease in clogging failure rate. This is because the product's mesh holes can effectively intercept food residues, reduce the workload of cleaning staff, and reduce the need for repairs caused by clogging of the drainage system. In addition, the product's modern and simple design style and bright appearance add a sense of professionalism and high-end to the hotel kitchen, meeting the hotel's high requirements for brand image and hygiene standards. By using this product, the hotel kitchen can improve the overall cleaning efficiency and service quality, provide guests with a better and more hygienic dining experience, and enhance the hotel's market competitiveness and brand appeal.

Food Processing Workshop

In the food processing workshop, Stainless Steel Sink Bottom Rack is an ideal choice to ensure the hygiene and efficiency of the production process. Its oil-resistant and waterproof performance and high-strength structural design enable it to withstand the large amount of oil and heavy pressure generated during food processing, while effectively filtering food residues and impurities to prevent them from entering the drainage system and causing pollution. According to the hygienic standard test of the food processing industry, the workshop using this product has a 70% reduction in the bacterial growth rate in the sink area and a 45% increase in cleaning efficiency. This is because the stainless steel material of the product has good antibacterial properties, and the electrolytic polishing surface further reduces the chances of bacterial attachment and reproduction. At the same time, the mesh holes of the product can effectively intercept food residues, reduce the workload of cleaning staff, and ensure the continuity and efficiency of the production process. By using this product, the food processing workshop can meet strict hygiene standards, improve product quality and safety, provide strong support for the sustainable development of the enterprise, and ensure that the food processing process meets industry specifications and hygiene requirements.

Home Cleaning Center

In the home cleaning center, the Stainless Steel Sink Bottom Rack can be used to improve the efficiency and quality of cleaning work. Its excellent filtering performance and oil and water resistance enable it to effectively handle various cleaning tasks, such as washing vegetables, fruits, tableware, etc. According to user feedback, the home cleaning center using this product has increased cleaning efficiency by 35%, and the sanitation of the sink area has been significantly improved. For example, when washing a large number of vegetables and fruits, users can place the grid at the bottom of the sink to effectively filter out dirt and impurities and prevent them from entering the drainage system and causing blockage. At the same time, the high-strength structural design of the product can withstand the pressure of heavy objects, and users can safely place various cleaning utensils and containers on the grid without worrying about product damage or deformation. By using this product, the home cleaning center can improve the convenience and efficiency of cleaning work, provide a more hygienic and tidy cleaning environment for the family, meet the various needs of daily household cleaning, and make cleaning work easier and more efficient.

Daily cleaning and maintenance

In order to keep the Stainless Steel Sink Bottom Rack clean and hygienic, it is recommended to perform simple cleaning and maintenance every day. Use a soft damp cloth or sponge to gently wipe the surface of the grid to remove residual food residues and dust. For stubborn stains, a small amount of neutral detergent can be used to assist cleaning, but avoid using detergents containing abrasives to avoid scratching the stainless steel surface. After cleaning, rinse thoroughly with clean water and wipe dry with a dry cloth to avoid water stains and scale formation. According to actual tests, such simple cleaning every day can effectively reduce the accumulation of stains and maintain the bright luster and hygienic condition of the grid. For example, home users can wipe the surface of the grid with a damp cloth after each use of the sink to remove food residues and oil stains left when washing dishes or cutting vegetables, ensuring that the grid is always clean and ready for the next use. This daily cleaning habit can not only extend the service life of the product, but also provide users with a more hygienic use environment and ensure the smooth progress of kitchen cleaning work.

Deep cleaning

Perform a deep cleaning once a week to remove stubborn stains and bacteria that may have accumulated. First, remove the grid from the sink and soak it in warm water for 10-15 minutes to loosen the attached dirt. Then, use a soft brush to gently scrub the surface of the grid, especially the grid holes and edges, to remove deep dirt and food residues. For areas with heavy oil stains, you can use a special stainless steel cleaner and follow the product instructions. Apply the cleaner evenly to the oily area, scrub gently and rinse with clean water. Finally, wipe the grid thoroughly with a dry cloth to ensure that no moisture remains. Deep cleaning can effectively restore the brightness and hygiene of the grid and extend its service life. For example, home users can perform deep cleaning on weekends or in their free time, soak the grid in warm water, add a small amount of detergent, and then carefully scrub each part to ensure that dirt and bacteria are thoroughly removed. After deep cleaning, the grid will be refreshed, providing more reliable protection for kitchen cleaning work.

Check the foot pads regularly

Check the plastic foot pads of the product once a month to ensure their stability and integrity. Check whether the foot pads are worn, deformed or detached. If there are any problems, replace the foot pads in time to maintain the stability of the grid and protect the sink. According to actual tests, regular inspection and replacement of foot pads can effectively prevent the grid from sliding and the sink from scratching, and extend the service life of the product. For example, home users can check the condition of the foot pads during monthly cleaning. If they find signs of wear or deformation on the foot pads, they can contact the manufacturer to purchase original accessories for replacement. Correct installation and maintenance of the foot pads can ensure that the grid remains stable during use, avoid grid displacement or sink scratches caused by damage to the foot pads, and provide users with a safer and more reliable experience.

Anti-corrosion treatment

Regularly treat the stainless steel grid with anti-corrosion to enhance its corrosion resistance, especially in humid or high humidity environments. Special stainless steel cleaners and protectants can be used and operated according to the product instructions. Cleaners can effectively remove surface dirt and oxides, while protectants form a protective film on the surface to prevent erosion by moisture and oxygen. According to material testing, the surface corrosion rate of stainless steel grids that have been regularly treated with anti-corrosion treatment can be reduced by more than 80%, and the service life can be extended by 3-5 times. For example, home users can use stainless steel special cleaners and protective agents to fully maintain the grids during the annual season change period. First use a cleaner to remove the dirt and oxide layer on the surface of the grid, and then apply the protective agent evenly on the surface. After it is naturally air-dried, the corrosion resistance of the grid will be significantly improved, ensuring that it maintains good performance and appearance in long-term use.

Avoid scratches with sharp objects

During use, avoid using sharp cleaning tools or placing objects with sharp edges on the grid to avoid scratching the stainless steel surface. Scratches from sharp objects will not only affect the aesthetics of the grid, but may also damage the electrolytic polishing layer, reducing its anti-fouling and easy-to-clean performance. If you need to deal with stubborn stains or cut food, it is recommended to use soft cleaning tools and special cutting boards. According to actual tests, the surface scratch rate of the grid that avoids scratches from sharp objects is reduced by 90%, and it always maintains a bright and new appearance. For example, when cutting vegetables or preparing seafood, home users should place the ingredients on a dedicated cutting board instead of directly on the grid. At the same time, choose soft cleaning tools such as sponges or soft-bristled brushes for daily cleaning work, and avoid using steel wool or hard scrapers to protect the surface of the grid from damage and extend its service life and appearance.

Storage environment control

When storing the Stainless Steel Sink Bottom Rack, choose a dry, ventilated environment to avoid moisture and high temperature. The ideal storage temperature is 5℃ to 35℃, and the relative humidity does not exceed 60%. Place the grid on a stable surface to avoid bending or deformation. At the same time, ensure that the storage location is away from chemicals and corrosive substances to prevent damage to the stainless steel material. A good storage environment can extend the service life of the product and ensure that its performance is not affected. For example, home users can store the grid in a kitchen cabinet or storage shelf, avoid direct contact with the ground or place it against the wall to prevent moisture and external factors. When not in use for a long time, you can wrap the grid with a soft cloth or paper towel to further protect its surface from dust and dirt. Check the storage status regularly to ensure that the grid is not damaged during storage and is fully prepared for the next use so that it always maintains good working condition and performance.

A Stainless Steel Sink Bottom Rack is designed to safeguard the sink's surface from scratches, dents, and wear caused by dishes and utensils.

It preserves the sink's finish, extends its lifespan, and reduces noise from dishwashing activities.

Yes, it typically requires a quick rinse or wipe-down to remove debris and maintain cleanliness.

Most protectors are available in various sizes to accommodate different sink dimensions, ensuring a snug fit.

Jiangmen Pengjiang District Zhengyong Hardware Co., Ltd.

Jiangmen Pengjiang District Zhengyong Hardware Co., Ltd. was founded in 2017. Since its establishment, the company has obtained CUPC certification and is based on the ISO90001:2015 quality management system. The company specializes in the production of kitchen and bathroom supporting shelves, sink racks, drain baskets and other hardware products. Adhering to the business philosophy of "quality first and marketing first" and management as the soul, we have established internal R&D, production and other departments. We are a professional kitchen and bathroom hardware accessories manufacturing company integrating R&D, design, production and sales. The products have novel styles and stable quality, and can be customized according to customer needs.

On the basis of absorbing advanced domestic and foreign technologies and years of experience in kitchen and bathroom hardware supporting products, the company's product production stability and reliability have been recognized and trusted by cooperative customers. While creating high-quality kitchen and bathroom hardware products and improving the quality of life, the company insists on using corporate culture to enhance the core competitiveness of the company, so that the company can establish a correct and good social image in its development. Maintain long-term cooperative relationships with domestic first-tier brand companies.

"Professional", "reliable" and "accurate" are our company's production spirit and service belief. It is precisely because of this that our company's products are sold at home and abroad and in major and medium-sized cities in China, and are well received and praised by users. We strictly ensure that product quality passes the test. Every piece of fine quality. As the company continues to develop, Zhengyong will adhere to the business philosophy of pioneering innovation and advancing with the times, producing in China and facing the world.