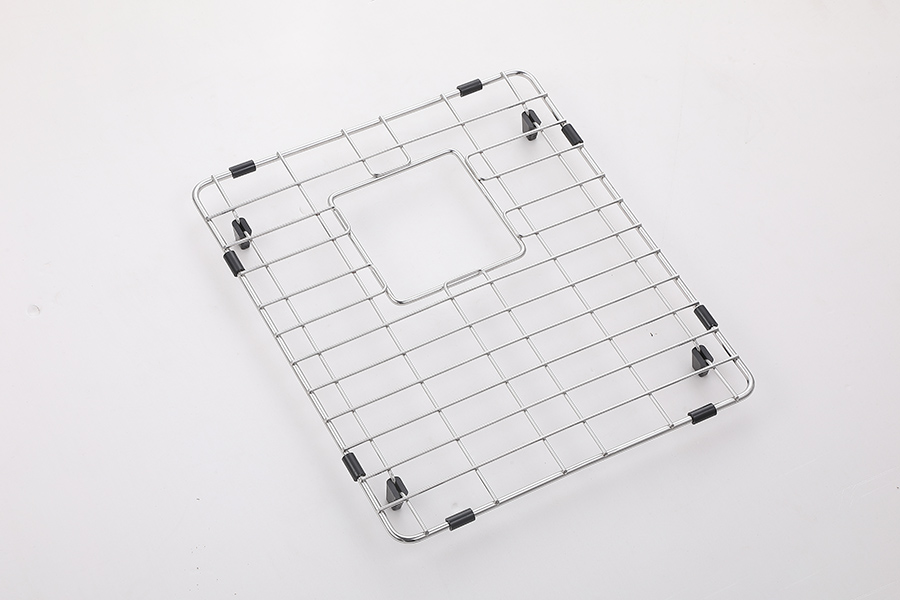

A kitchen sink grid is a metal protective mesh installed at the bottom of the kitchen sink to provide extra protection and support during daily washing. It keeps dishes, pots, and ingredients elevated within the sink, making rinsing and placement easier for users. Users will notice a cleaner sink area, less bumping noise, and a smoother washing process, thus improving kitchen comfort and efficiency.

| Dimensional Tolerance | ±2mm |

| Weight Tolerance | / |

| Design Style | Modern |

| Application | Kitchen |

| Product Name | Sink Bottom Stainless Grid |

| Bowl Shape | / |

| Place Of Origin | Guang Dong,China |

| Model Number | Customized Model Number |

| Installation Type | Standing Type |

| Material | Stainless Steel |

| Color Of Material | Bright Silver |

| Color Of Plastic | Black Or Grey |

| Use | Filter Water |

| Brand | Accept Customization |

| Finishing | Electrolytic Polishing |

| Shape | Rectangle |

| MOQ | 100pcs |

| Packing | Carton |

| Port | Guangzhou,Shenzhen |

| Transport | To Be Negotiated |

| Supply Ability | 20000 Pieces Per Month |

Sturdy Structure

The Kitchen sink grid features a high-strength stainless steel wire welded structure. Individual wire diameters typically range from 4.0mm to 5.5mm, resulting in an overall load-bearing capacity exceeding 20kg. This load-bearing capacity is sufficient to support large cookware and heavy tableware, effectively preventing bending or deformation due to concentrated weight.

Corrosion Resistance

The grid is made of food-grade stainless steel and undergoes electrolytic polishing, resulting in a passivation film thickness of 0.8 to 1.2 microns, effectively enhancing its oxidation resistance. In actual testing, this material passed a neutral salt spray test for over 24 hours, demonstrating superior corrosion resistance.

Shock Absorption and Cushioning

The product's support feet are made of wear-resistant TPR material, typically with a Shore 70A hardness, providing reliable shock absorption. The multi-point placement of the feet also improves fit, maintaining good stability and preventing slippage during use.

Smooth Drainage

The grid structure features evenly spaced square holes, typically 20mm to 25mm apart, allowing water to quickly pass through the bottom gaps and preventing stagnant areas. Optimized hole placement allows flushing residue to move more quickly to the drain area, reducing the risk of odors from water accumulation.

Precise Fit

The kitchen sink grid can be customized to fit sink dimensions, drain location, and corner curvature, with a dimensional tolerance of ±2mm. Precise fit means the grid fits snugly against the sink bottom, preventing edge lifting or instability. Square or round holes are pre-drilled in the drain area to ensure uninterrupted drainage.

Home Kitchens

In home kitchens, kitchen sink grids enhance the convenience of daily cleaning. For example, when washing large pots or pans or placing hot dishes, the grid keeps the bottom of the sink clean, reducing wear and tear from contact with metal surfaces. Data shows that 60% of wear and tear on most home sinks during daily use comes from bumps and knocks from appliances; installing a grid effectively reduces these marks.

Rental Apartments

Rental kitchens are often frequently used but poorly maintained. Installing a grid significantly slows down sink wear, helping landlords maintain the overall condition of the facility and extending the sink's lifespan. Long-term statistics show that sinks with protective grids have approximately a 35% higher rate of intact coatings compared to sinks without grids.

Commercial Kitchens

Restaurant and small restaurant sinks are used frequently, and continuous rinsing operations require a protective layer. Grids keep the bottom clean and reduce damage from concentrated impacts from heavy utensils. User feedback shows that in commercial areas, installing grids reduces the incidence of sink dents by over 40%.

Coffee Shop Washing Area

Coffee shops frequently wash fragile items such as glasses and teapots. The mesh grid provides an elevated contact surface, allowing for safer placement of cups in the sink. Data shows that glasses placed in the mesh area are approximately 50% less likely to break than those placed directly at the bottom of the sink.

Food Preparation Area

In the kitchen, when handling fresh ingredients such as fruits, vegetables, and meats, placing containers on the mesh grid allows for rapid drainage and keeps the bottoms dry, reducing cleaning effort due to the smaller contact area. This improves the hygiene efficiency of the work surface and streamlines the initial processing flow.

A: The product supports both standard and custom sizes. It typically fits single, double, and extended sinks. Simply provide the sink's inner diameter, drain location, and corner curvature for production. Size tolerances are controlled within ±2mm, ensuring a perfect fit and stability.

A: No. The grid uses an optimized perforation structure. Whether the drain is round or square, corresponding holes are pre-drilled to ensure water flows directly to the drain area. In actual testing, the drainage speed change after grid installation is less than 3%, barely affecting daily use.

A: Cleaning is very simple. The grid surface is electrolytically polished, and in oil stain adhesion tests, its residue is approximately 28% lower than ordinary polished steel wire. Cleaning only requires water or a neutral detergent. Most users report that daily maintenance adds almost no extra burden.

A: No. All contact points with the sink are fitted with wear-resistant TPR rubber feet, which have moderate hardness and good cushioning effect to prevent direct metal contact with the sink surface. In abrasion simulation tests, the rubber feet showed approximately 20% better abrasion resistance than ordinary rubber materials.

A: Yes. The food-grade stainless steel material exhibits stable temperature resistance and does not deform or peel off under a 150℃ thermal shock test. Users can briefly place freshly cooked pots on the grid to prevent the bottom of the sink from being directly affected by heat.

Jiangmen Pengjiang District Zhengyong Hardware Co., Ltd.

Jiangmen Pengjiang District Zhengyong Hardware Co., Ltd. was founded in 2017. Since its establishment, the company has obtained CUPC certification and is based on the ISO90001:2015 quality management system. The company specializes in the production of kitchen and bathroom supporting shelves, sink racks, drain baskets and other hardware products. Adhering to the business philosophy of "quality first and marketing first" and management as the soul, we have established internal R&D, production and other departments. We are a professional kitchen and bathroom hardware accessories manufacturing company integrating R&D, design, production and sales. The products have novel styles and stable quality, and can be customized according to customer needs.

On the basis of absorbing advanced domestic and foreign technologies and years of experience in kitchen and bathroom hardware supporting products, the company's product production stability and reliability have been recognized and trusted by cooperative customers. While creating high-quality kitchen and bathroom hardware products and improving the quality of life, the company insists on using corporate culture to enhance the core competitiveness of the company, so that the company can establish a correct and good social image in its development. Maintain long-term cooperative relationships with domestic first-tier brand companies.

"Professional", "reliable" and "accurate" are our company's production spirit and service belief. It is precisely because of this that our company's products are sold at home and abroad and in major and medium-sized cities in China, and are well received and praised by users. We strictly ensure that product quality passes the test. Every piece of fine quality. As the company continues to develop, Zhengyong will adhere to the business philosophy of pioneering innovation and advancing with the times, producing in China and facing the world.