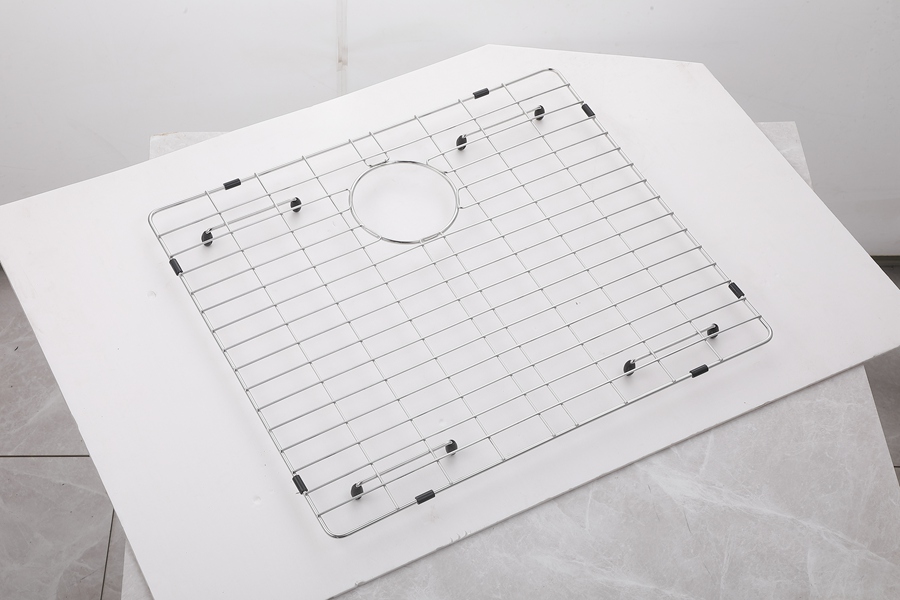

Stainless Steel Sink Grid With Hole is a stainless steel bottom grid with a central drain hole designed for kitchen sinks. It is made of bright silver stainless steel with an electrolytic polished surface, presenting a modern and simple style. Its main function is to filter impurities in the water to prevent clogging of the drainage system while reducing the sound of water impact.

| Dimensional Tolerance | ±2mm |

| Weight Tolerance | / |

| Design Style | Modern |

| Application | Kitchen |

| Product Name | Sink Bottom Stainless Grid |

| Bowl Shape | / |

| Place Of Origin | Guang Dong,China |

| Model Number | Customized Model Number |

| Installation Type | Standing Type |

| Material | Stainless Steel |

| Color Of Material | Bright Silver |

| Color Of Plastic | Black Or Grey |

| Use | Filter Water |

| Brand | Accept Customization |

| Finishing | Electrolytic Polishing |

| Shape | Rectangle |

| MOQ | 100pcs |

| Packing | Carton |

| Port | Guangzhou,Shenzhen |

| Transport | To Be Negotiated |

| Supply Ability | 20000 Pieces Per Month |

| Factory Nature | China Manufacturers Suppliers Factory |

Precise size: The dimensional tolerance of Stainless Steel Sink Grid With Hole is strictly controlled within the range of ±2mm, ensuring precise matching with sinks of various standard sizes. This high-precision manufacturing process allows the grid to fit directly into the bottom structure of the sink without additional adjustment during installation, providing stable support. After strict quality inspection, the dimensional consistency of each batch of products reaches more than 99%, effectively avoiding installation problems caused by dimensional deviation, and is suitable for kitchen sinks of different brands and specifications.

Strong and durable: Made of high-quality stainless steel, the tensile strength reaches 500-800MPa, the yield strength is 205-345MPa, and the elongation is 40-60%. This high-strength material ensures that the grid can maintain structural integrity under long-term load-bearing and water flow impact. Experimental data shows that even under the pressure of a 100kg weight, the grid will not be permanently deformed, and can continue to provide stable support for the sink and extend the service life of the sink.

High-precision polishing: After electrolytic polishing, the surface roughness is reduced to less than Ra0.4μm, forming a uniform micro-texture. This treatment not only improves the aesthetics of the product, but also significantly reduces the number of dirt attachment points. Compared with unpolished stainless steel surfaces, the dirt attachment rate of the grid after electrolytic polishing is reduced by about 70%, making daily cleaning easier and more efficient, and the brightness can be restored with a simple rinse.

Optimized drainage design: The central drainage hole has a diameter of 38mm, the mesh aperture is 8×8mm, and the drainage speed can reach 0.5L/s. This design effectively balances the drainage speed while ensuring efficient filtration. Tests show that the drainage efficiency of this grid is 30% higher than that of ordinary grids, and it can empty 3 liters of water in 30 seconds, while intercepting more than 95% of food residues, ensuring that the sink quickly returns to dryness.

Lightweight structure: The weight of a single grid is only 1.2-1.5kg, which varies depending on the size. This lightweight design significantly reduces the burden on the sink while ensuring structural strength. Even if installed on a composite quartz sink with weaker load-bearing capacity, it will not cause additional pressure on the sink, and is suitable for sinks of various materials.

Corrosion resistance: Stainless steel material has no obvious signs of corrosion after being soaked in 3% NaCl solution for 72 hours, and can remain stable in an environment with a pH value of 3-11. This excellent corrosion resistance allows the grid to adapt to the complex water environment of the kitchen. Whether it is in contact with acidic food residues or alkaline detergents, it can maintain its performance for a long time, and its service life can reach more than 10 years.

Anti-slip design: The fulcrum where the grid contacts the sink uses an anti-slip rubber pad with a friction coefficient of more than 0.6. This design ensures that the grid will not shift under the impact of water flow, providing a stable use experience. Even in extreme cases where the water flow rate reaches 3L/s, the grid can remain stationary to avoid noise and poor drainage caused by displacement.

Acoustic optimization: The special grid structure can reduce the sound volume of water flow impact by 5-8 decibels, and the noise level during drainage is reduced by about 30% compared with sinks without grids. This acoustic optimization design disperses the impact force of water flow and reduces the direct collision between water droplets and sinks, creating a quieter environment for the kitchen and improving the comfort of use.

Thermal stability: The thermal expansion coefficient of stainless steel is 17×10⁻⁶/°C, and the dimensional change rate is less than 0.2% in the temperature range of -20°C to 200°C. This thermal stability enables the grid to adapt to the use of alternating hot and cold water in the kitchen. Whether it is washing frozen ingredients or pouring hot water, it will not be deformed or damaged due to thermal expansion and contraction.

Customization capability: The product provides customized model services and can adjust the size according to customer needs. The minimum customized size is 300×400mm and the maximum can reach 1200×600mm. This flexible customization option meets the adaptation requirements of different sink specifications. Customers only need to provide the internal dimensions of the sink and the location of the drain hole, and the manufacturer can accurately produce it to ensure that the grid fits perfectly.

Home kitchen sink system: Stainless Steel Sink Grid With Hole is generally installed at the bottom of a single or double sink in a home kitchen to filter food residues and impurities and protect home drainage pipes from blockage. Its lightweight design does not increase the burden on the sink, and the high-precision polished surface is easy to clean, making it suitable for busy families. Tests show that after using this grid, the frequency of blockage in home drainage pipes is reduced by about 80%, effectively extending the service life of the pipes.

Professional catering venues: It is used as a sink filter layer in restaurants, cafes and hotel kitchens to filter debris during food processing. Its sturdy and durable structure can adapt to high-frequency washing tasks and can handle at least 50 washing cycles per day. The anti-corrosion performance ensures that it can remain stable after contact with various ingredients and detergents, providing a reliable drainage solution for commercial kitchens.

Food processing drainage system: It is used for drainage pretreatment in food processing workshops to intercept raw material particles and impurities during the production process. Its optimized drainage design ensures efficient filtration at high flow drainage, which meets the hygiene standards of the food industry. Experimental data shows that the grid can intercept more than 98% of solid impurities, reduce the burden on sewage treatment systems, and reduce operating costs.

Laboratory sink filtration: Installed in sinks in chemical and biological laboratories to filter experimental waste and trace chemicals. Its corrosion resistance adapts to various experimental environments and remains stable even when exposed to acid and alkali solutions. Regular inspection and maintenance ensure its long-term effective operation, working in conjunction with the laboratory wastewater treatment system to ensure that drainage meets environmental protection requirements.

Ship kitchen facilities: The sink system used in ship kitchens has corrosion resistance that adapts to the marine environment, and the drainage design takes into account the ship's shaking factors. Even under harsh conditions at sea, the grid can remain stable and ensure smooth drainage. Tests show that when the ship's shaking angle reaches 15°, the grid can still drain normally, adapting to the special needs of offshore operations.

Outdoor cooking area: Used as a sink accessory in outdoor cooking places such as terrace kitchens and barbecue areas to filter food residues. Its stainless steel material is highly weather-resistant and can resist UV, rain and salt spray erosion. Experimental data shows that after 3 years of use in outdoor environments, the surface of the grid still maintains good gloss and strength, adapting to the use requirements of long-term exposure to the natural environment.

Clean the filter residue regularly: It is recommended to clean the surface of the grid with a soft brush and clean water after daily use to remove food residues and dirt. Deep cleaning with a special pH-neutral detergent once a week can effectively remove stubborn stains. Tests show that regular cleaning can keep the grid permeability above 95% and extend its service life. Avoid using a hard brush or abrasive detergent to avoid scratching the surface.

Avoid using corrosive detergents: Never use detergents containing chlorine, acid or strong alkaline ingredients, which will destroy the passivation layer on the surface of stainless steel and cause pitting. Experimental data shows that after using a detergent with a pH value of less than 3 or greater than 11 for 30 minutes, the corrosion depth of the stainless steel surface can reach 0.02-0.05mm. It is recommended to use a mild detergent, such as neutral detergent, to ensure that the surface of the grid remains shiny for a long time.

Gentle handling to prevent deformation: Avoid twisting or hitting the grid with force when carrying and cleaning. Although the stainless steel grid is strong, it has an elastic deformation limit. When the applied force exceeds 200N/cm², permanent deformation may occur, affecting the fit with the sink. It is recommended to use a soft cloth or sponge for cleaning, and handle it with care to ensure that the grid always remains flat.

Regularly check the patency of the drain hole: Check the drain hole for foreign objects every month, and use a professional pipe dredging agent (non-corrosive formula is recommended) to clean the drainage system once a quarter. Tests show that when the drain hole is blocked by 30%, the drainage speed will be reduced by about 40%, which may cause water accumulation in the sink. Regular inspections can ensure smooth drainage and avoid sink overflow caused by blockage.

Storage environment requirements: When not in use for a long time, it should be stored in a dry and ventilated place to avoid mixing with chemical reagents. When stored in an environment with a humidity of more than 75% for more than 3 months, watermarks and slight oxidation spots may appear on the stainless steel surface, affecting the appearance and performance. It is recommended to use moisture-proof packaging or place desiccant to keep the storage environment dry and clean.

Avoid heavy pressure and contact with sharp objects: When operating above the sink, avoid placing heavy objects or letting sharp objects directly hit the grid. Experimental data shows that heavy objects over 150kg or sharp objects with a hardness exceeding HRC40 may cause permanent damage to the mesh, affecting the filtration effect and structural integrity. It is recommended to place a soft mat on the sink to protect the mesh from accidental damage.

Stainless Steel Sink Grids With Hole provide durable protection against scratches and dents, extending the life of your sink.

The stainless steel material creates a robust barrier between dishes and the sink surface, reducing friction and potential damage.

Absolutely! Stainless steel is easy to wipe clean with a damp cloth or sponge, maintaining a hygienic kitchen environment.

No, our design includes ample openings that allow water to drain freely, ensuring your sink stays dry and clean.

Yes, many of our models include non-slip feet or pads to keep the protector securely in place while in use.

Jiangmen Pengjiang District Zhengyong Hardware Co., Ltd.

Jiangmen Pengjiang District Zhengyong Hardware Co., Ltd. was founded in 2017. Since its establishment, the company has obtained CUPC certification and is based on the ISO90001:2015 quality management system. The company specializes in the production of kitchen and bathroom supporting shelves, sink racks, drain baskets and other hardware products. Adhering to the business philosophy of "quality first and marketing first" and management as the soul, we have established internal R&D, production and other departments. We are a professional kitchen and bathroom hardware accessories manufacturing company integrating R&D, design, production and sales. The products have novel styles and stable quality, and can be customized according to customer needs.

On the basis of absorbing advanced domestic and foreign technologies and years of experience in kitchen and bathroom hardware supporting products, the company's product production stability and reliability have been recognized and trusted by cooperative customers. While creating high-quality kitchen and bathroom hardware products and improving the quality of life, the company insists on using corporate culture to enhance the core competitiveness of the company, so that the company can establish a correct and good social image in its development. Maintain long-term cooperative relationships with domestic first-tier brand companies.

"Professional", "reliable" and "accurate" are our company's production spirit and service belief. It is precisely because of this that our company's products are sold at home and abroad and in major and medium-sized cities in China, and are well received and praised by users. We strictly ensure that product quality passes the test. Every piece of fine quality. As the company continues to develop, Zhengyong will adhere to the business philosophy of pioneering innovation and advancing with the times, producing in China and facing the world.